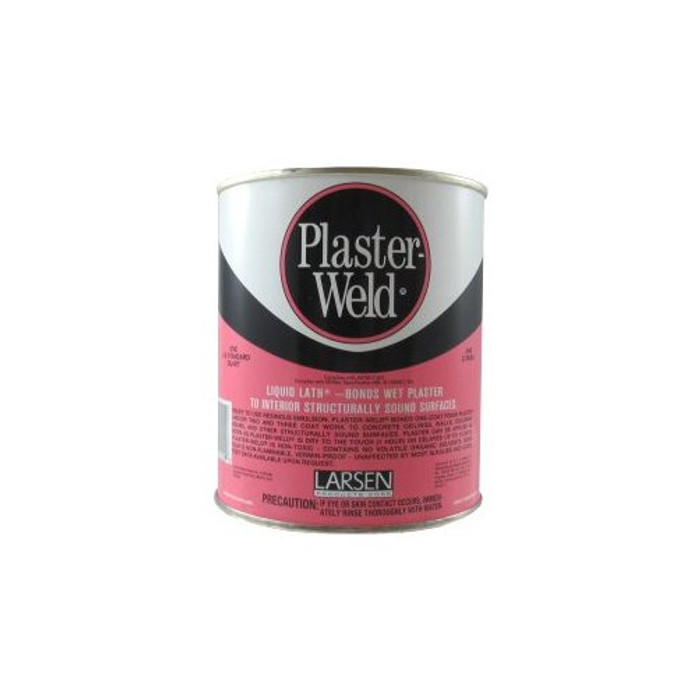

Inspection of bonding agent: Prior to applying plaster, inspect bonding agent application to assure a continuous pink film over the entire bonding surface.Application of wallpaper to newly bonded plastered Wait 60 days before applying bonding agent over newly (NOTE: Painted surfaces must be sound, washable andįirmly adhered to the substrate. Roller, or spray to form a continuous pink film over the entire surface. Application of bonding agent: Apply Plaster-Weld® uniformly using brush.Form release agents, curingĬompounds, hardeners, and sealers must be compatible with Plaster-Weld®. Mildew, rust, laitance, or efflorescence.

PLASTER WELD FREE

Surfaces to receive Plaster-Weld® MUST BE STRUCTURALLY SOUND ANDĬLEAN, free from loose material, dust, dirt, oil, grease, wax, loose paint,.Packaging: Plaster-Weld® is available in 5 gallon pails, 1-gallon cans, and quart containers. Gallon, depending on method of application, temperatures, porosity and texture Non-deteriorating bond retainsĬoverage: Plaster-Weld® covers approximately 300 to 400 square feet per Life Expectancy: Lab tested and field proven. Freeze-thaw stable.Įnclosed mice exposed to 30 cc volatized bonding agent for 1 hr. Avg.ĥ cycles freeze (-10 degrees F and thaw). 28 days.ĪSTM C-109 (specimens brought to 35 degrees F for 1 hr., then to 310ĭegrees F for 2 hrs). Occurred in the cementitious material, not in the bond.

Tensile Bond Strength: ASTM C-631 (pulling apart bonded cement briquet halves). Do not apply over water soluble paints, ie. Plaster-Weld® can be used over paints having oil, rubber, or vinyl bases, and over silicone-treated surfaces, as well as latex paints. sheet lead in x-ray rooms) and marble are suitable surfaces. Concrete, brick, block, glass, ceramic tile, wallboard, metals (e.g. Plaster-Weld® prepares the surface to allow you to plaster directly to concrete over electric radiant heat cable, and to bond cement mortar beds to smooth concrete for installation of rigid foam installation. Uses: Designed for interior use only, Plaster-Weld® provides high performance bonding of one-coat finish plaster and/or two and three coat work to concrete ceilings, walls, columns, beams, and other structurally sound surfaces.

Description : Plaster bonding agent interior “plaster-weld”.

0 kommentar(er)

0 kommentar(er)